PREDICT.360

Predictive Maintenance Reimagined

Predict 360: AI-Powered Predictive Maintenance

Solveit 360 presents Predict 360, an AI/ML-based predictive condition monitoring solution. Designed for prime movers in mission-critical systems, it leverages advanced technology to provide proactive insights, ensuring operational efficiency and minimizing downtime.

Solveit leverages the evolving tech landscape, particularly AI, ML, and Deep Learning, to drive innovation. Industries are rapidly adopting AI for operational improvements, efficiency gains, and emission reductions. Our solutions, rooted in these technologies, enable organizations to reduce human error and move towards autonomous operations. We utilize Deep Learning's neural networks, as seen in our Predict 360 engine, to analyze complex data patterns, providing advanced insights and predictive capabilities. This empowers businesses to make informed decisions and optimize their processes.

Solveit's AI technology revolutionizes filtration systems through proactive monitoring. Our algorithms detect motor anomalies like bearing failures and analyze filter aging, preventing inefficiencies. By identifying unusual patterns and estimating filter lifespan, we ensure optimal performance and minimize downtime. This empowers businesses to maintain peak operational efficiency and reduce maintenance costs. Solveit's AI-powered system uses regression and deep learning for precise condition monitoring. Deployment involves factory testing, on-site learning, and continuous real-time tracking. This ensures accurate predictions and actionable insights, optimizing performance and minimizing downtime for mission-critical systems.

- Cost Savings:Predict 360 reduces Total Cost of Ownership (TCO) by minimizing unplanned downtime and optimizing maintenance schedules.

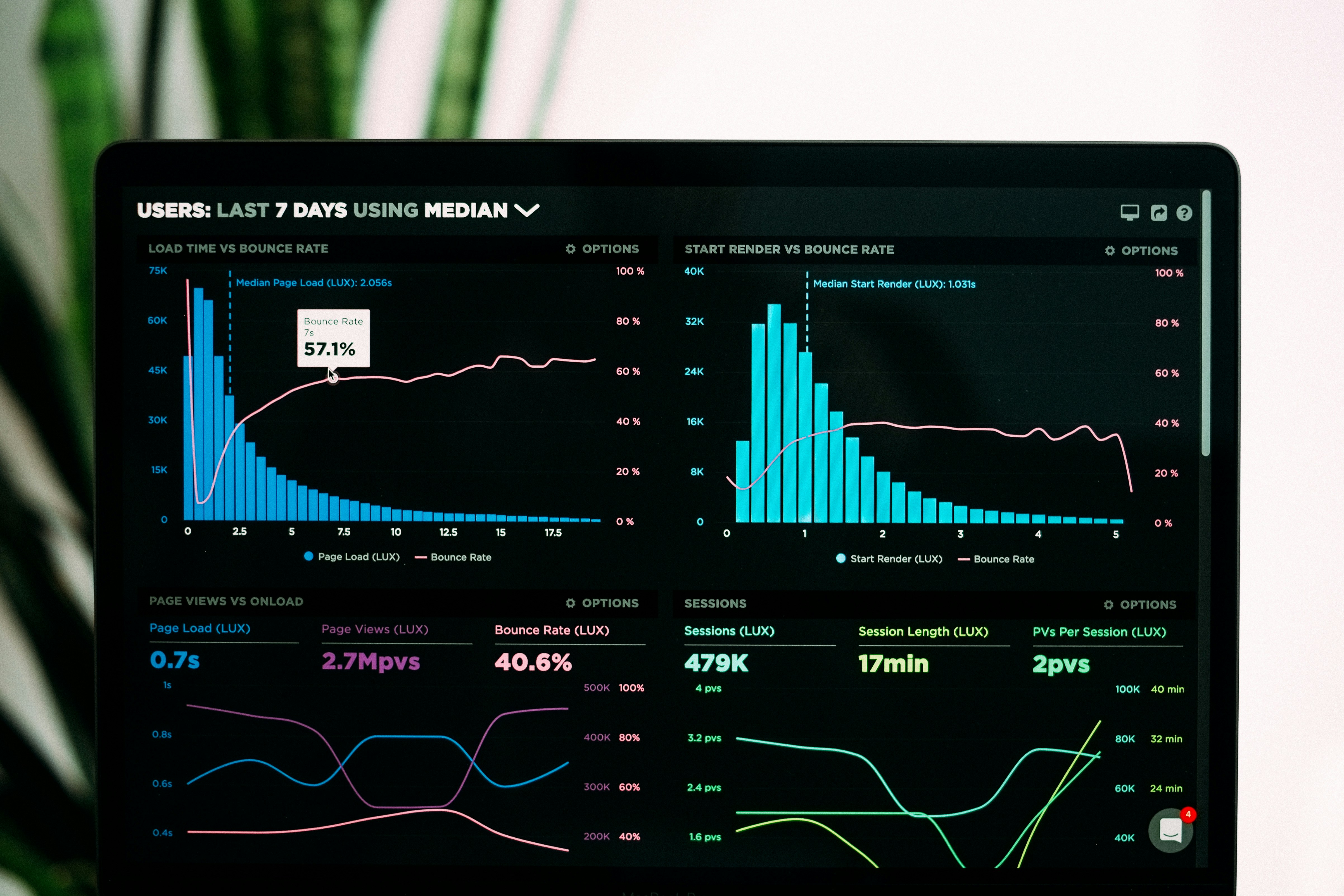

- Maximized Asset Uptime:The system proactively detects anomalies and monitors performance, leading to reduced energy consumption and improved productivity.

- Real-time KPI Monitoring:Predict 360 provides real-time dashboards for enhanced data-driven insights.

- Informed Teams:Plant Operations and Maintenance teams are kept informed and responsive through the system's monitoring capabilities.

- Overall Operational Efficiency:The system contributes to overall operational efficiency by improving maintenance, reducing downtime, and providing valuable insights.